50 years of engineering excellence: the Quiko story

What does it take to build a gate automation system that people trust for generations?

It takes more than engineering. It takes a philosophy , one built on precision craftsmanship, deep customer understanding, and the discipline to maintain quality standards across decades of industry change. Since 1968, Quiko has done exactly that. Founded in the Veneto region of North East Italy, this producer of gear motors and automation solutions has spent over fifty years proving that dependability is not a feature to be marketed, but a standard to be earned.

In this article, you will discover the story behind one of Italy’s most enduring automation brands, understand what truly separates a superior gate automation system from an average one, and learn why thousands of installers and homeowners continue to choose Quiko when performance and longevity are non-negotiable.

Discover Quiko’s full range of gate automation systems , 50 years of Italian engineering reliability.

Explore the product range

What is a gate automation system?

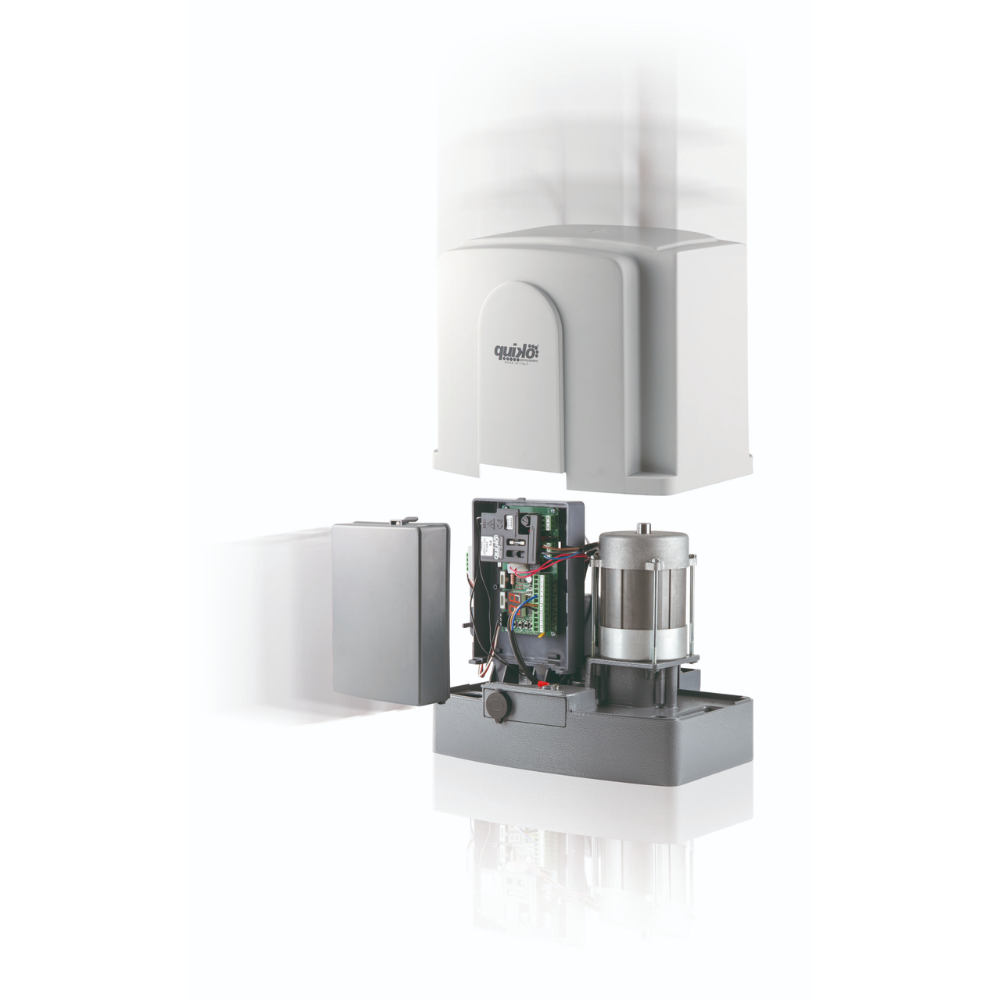

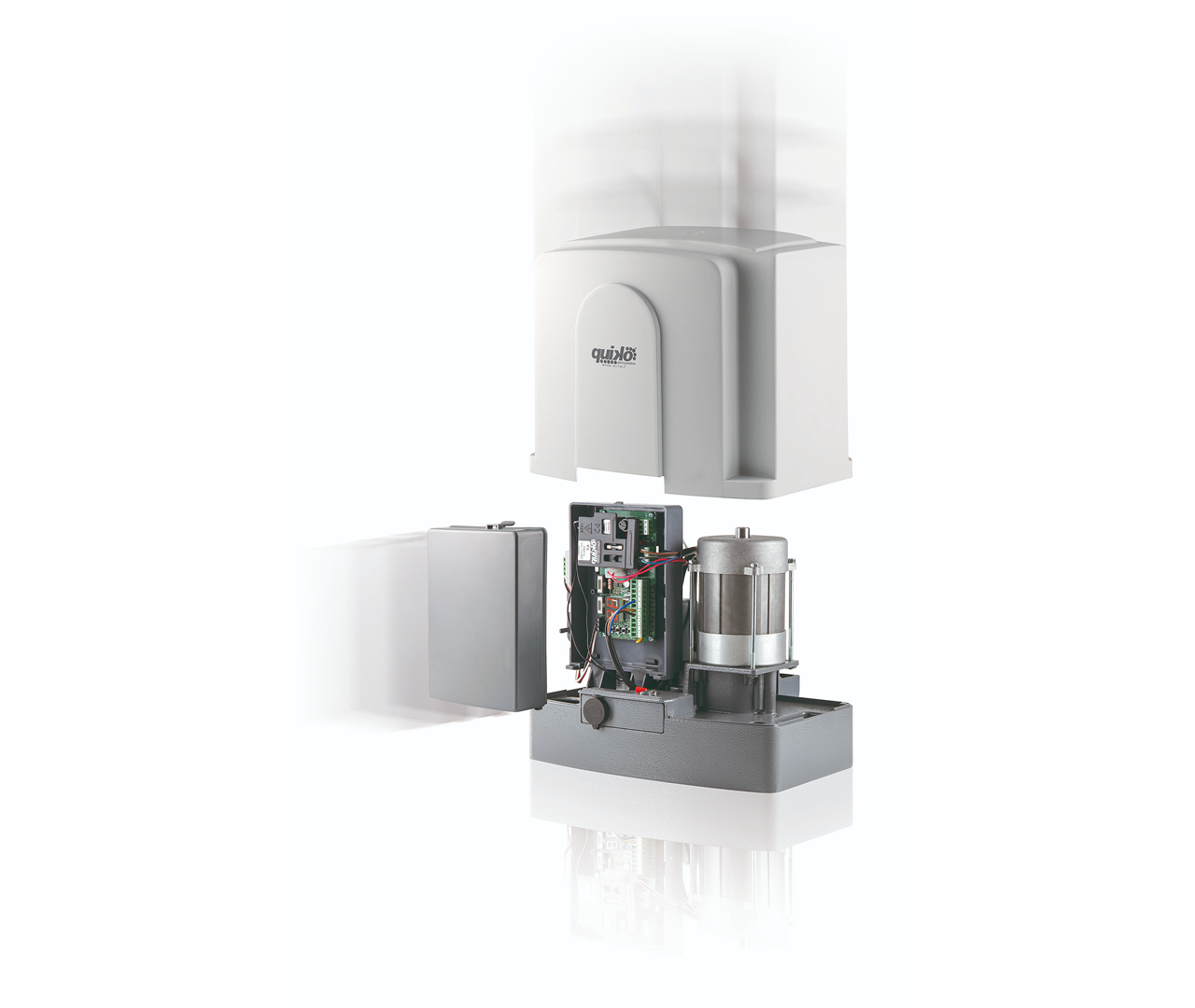

A gate automation system is an integrated set of components that allows a gate to open and close automatically, either through remote control, a keypad, a smartphone app, or sensor-based triggering. At its core, the system relies on a gear motor , the mechanical heart of the operation , which converts electrical energy into the precise movement needed to drive the gate.

Modern gate automation systems typically include the motor unit itself, a control board, safety sensors, receiver units, and remote controls or keypads. When all components are properly engineered and installed, the result is seamless, safe, and repeatable gate movement that requires minimal user intervention.

The technology applies equally to residential driveways, commercial properties, agricultural land, and industrial facilities. Whether the requirement is an automatic sliding gate opener for a wide driveway entrance or a swing gate opener kit for a traditional residential property, the underlying principle remains the same: dependable, controlled motion delivered consistently over thousands of operating cycles.

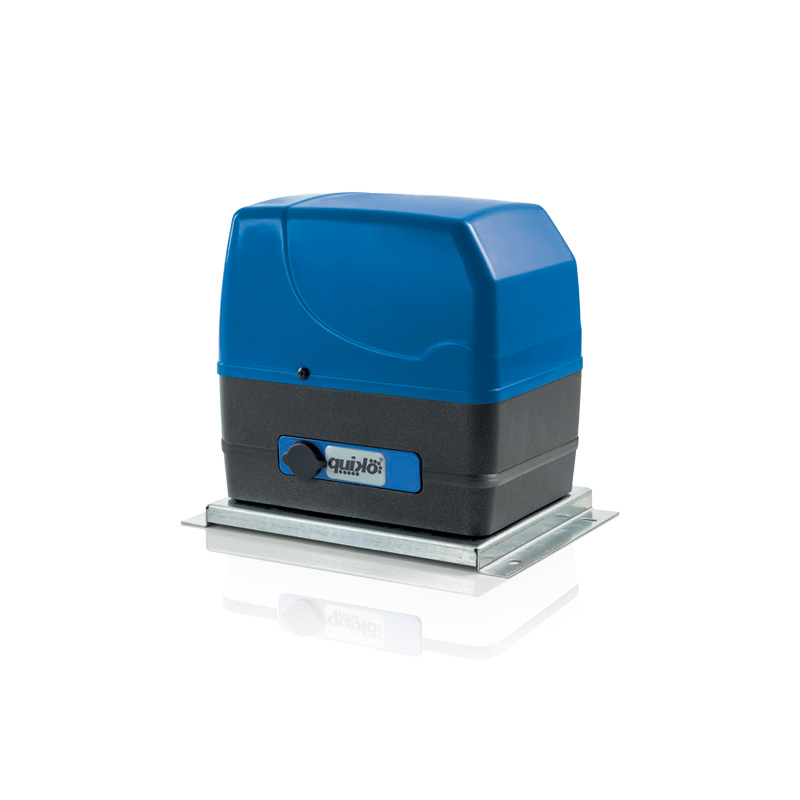

Photo courtesy of Quiko Italy , All rights reserved

The Quiko story: five decades of italian manufacturing

Quiko’s origins date back to 1968, a period when Italian production was establishing itself as a global benchmark for precision engineering and quality craftsmanship. The founders brought with them the values that have long defined Venetian business culture: meticulous attention to detail, long-term thinking, and a deep sense of responsibility toward the customer.

Over the following decades, Quiko grew steadily , not through aggressive expansion or short-term opportunism, but through the slower, more durable process of building a reputation. Each product that left the facility in North East Italy carried with it the weight of accumulated knowledge: an understanding of materials, tolerances, real-world operating conditions, and the particular demands that automation systems face over years of daily use.

By the time Quiko reached its fiftieth year in operation, the company had evolved significantly without losing its founding character. Technological advancement had been embraced at every stage, from the adoption of new fabrication processes to the development of more sophisticated motor designs and control systems. Yet the core proposition remained unchanged: deliver solutions that work dependably, last durably, and serve the customer’s actual needs.

This balance between heritage and innovation is not merely a marketing concept for Quiko. It is the operational reality of a company that has navigated half a century of change in the automation industry and emerged with both its standards and its customer relationships intact.

Photo courtesy of Quiko Italy , All rights reserved

Types of gate automation: finding the right solution

Understanding the different types of gate automation is essential before selecting the right system. The two primary categories are sliding gate automation and swing gate automation, each with distinct engineering requirements.

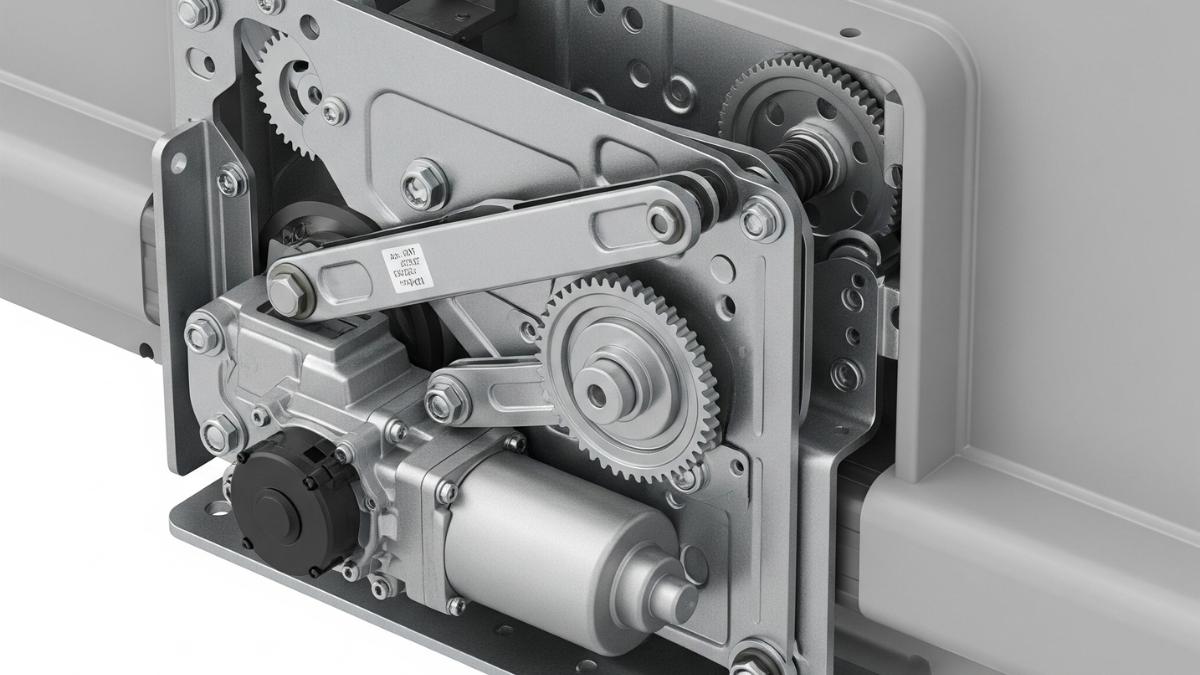

Sliding gate automation systems are designed for gates that travel horizontally along a track. These are common in properties where there is limited space in front of the gate for the leaf to swing outward. The gear motor at the heart of this system needs to deliver high torque while maintaining smooth, controlled movement.

Photo courtesy of Quiko Italy , All rights reserved

Swing gate automation systems are suited to traditional hinged gates, either single or double leaf. A heavy duty swing gate opener must handle the mechanical stress of repeatedly starting and stopping a pivoting load, often in exposed conditions that include temperature extremes, moisture, and wind resistance. For residential applications, swing gate opener kits offer a practical solution that can be adapted to a wide range of gate sizes and weights.

Beyond these two core categories, the market offers increasingly sophisticated options, including automatic gate openers with keypad entry, integrated intercom systems, and smartphone connectivity. The key to a successful installation lies not in selecting the most complex system available, but in matching the automation to the precise physical and operational requirements of the application.

What makes the best gate automation system?

The question of what constitutes the best gate automation system does not have a single universal answer. It depends on application, environment, frequency of use, and the individual priorities of the user. That said, several characteristics consistently distinguish superior systems from average ones.

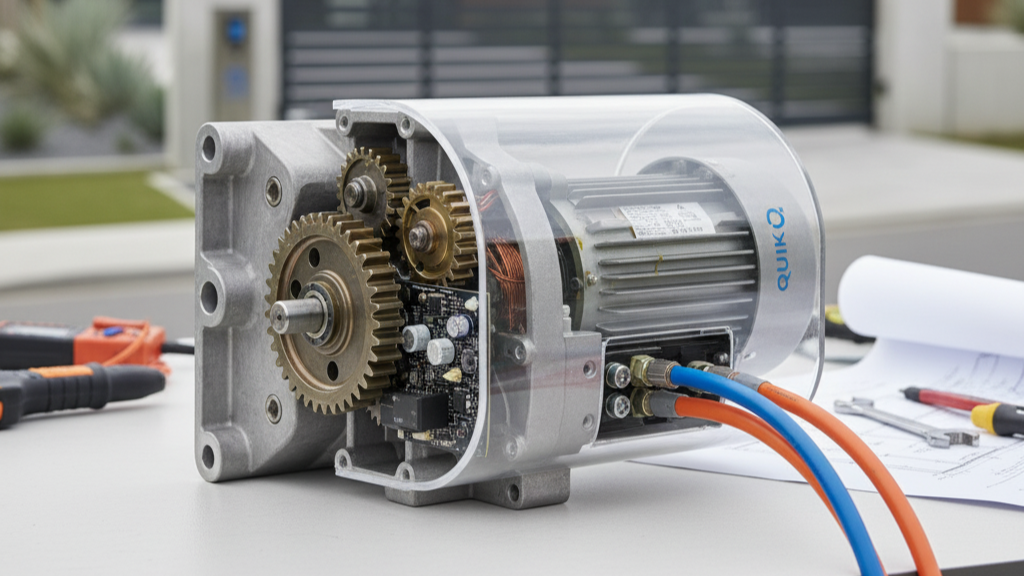

Proven performance over time is the primary consideration. A gate automation system is expected to operate correctly thousands of times across its lifespan. The mechanical components, particularly the gate opener motor, must be engineered to maintain output under repeated stress without progressive degradation. This demands quality materials, precision manufacturing tolerances, and thermal management that prevents overheating during intensive use cycles.

Durability in exterior conditions is equally important. Gate automation systems are permanently exposed to weather. UV radiation, rain, frost, humidity, and dust all impose continuous demands on enclosures, seals, lubricants, and electronic components. Systems that perform adequately in laboratory conditions but deteriorate rapidly in real-world environments represent a hidden long-term cost.

Customizability matters considerably in a market where no two installations are identical. Gate dimensions, weight, opening frequency, power supply conditions, and user interface preferences all vary. A producer that offers configurable solutions rather than rigid off-the-shelf products delivers measurably better outcomes for both installers and end users.

Finally, the availability of experienced technical support and the maker’s depth of industry knowledge play a role that is often underestimated at the point of purchase but becomes critical during installation, commissioning, and maintenance.

Request a free consultation and find the perfect automation system for your needs.

Get in touch with Quiko

Quiko’s product range: engineering for every application

Quiko’s catalog of gear motors and gate automation systems reflects the breadth of knowledge accumulated over five decades of engineering practice. The range spans solutions for lightweight residential swing gates through to heavy duty swing gate openers built for demanding industrial applications, covering both sliding and swing gate configurations.

Each product is developed around the same foundational principles: robust mechanical construction, solid electrical performance, and design flexibility that allows adaptation to customer-defined requirements. The gear motors are characterized by high torque output relative to their physical footprint, smooth operational characteristics that extend gate hardware life, and protective designs suited to continuous exterior exposure.

Importantly, Quiko’s approach to product development is customer-centric rather than catalogue-driven. Where standard products do not fully address a stated requirement, customization is available , a capability that reflects the company’s production depth and its understanding that the most demanding customers are often those with the most individual needs.

Gate automation system price and value

Gate automation system price is a consideration that deserves careful framing. The initial purchase cost represents only part of the true economic picture. Installation costs, maintenance requirements, spare parts availability, and the cost of system failures all contribute to the total cost of ownership over a gate automation system’s operational life.

Systems positioned at the lower end of the market frequently carry hidden long-term costs in the form of higher failure rates, limited spare parts availability, and shorter service intervals. Conversely, a system built to a high specification with quality components and backed by an experienced producer tends to deliver significantly better value over a five- to ten-year ownership period, even if the initial investment is higher.

Quiko’s positioning reflects this value-over-price philosophy. The company builds to a standard that prioritizes longevity and proven performance, recognizing that customers , whether residential homeowners or professional installers servicing commercial accounts , ultimately measure a product’s worth in terms of its output across years of operation, not merely its cost at the point of purchase.

Why Quiko remains the trusted choice

In a market populated by producers of varying backgrounds, experience levels, and quality commitments, Quiko’s five decades of uninterrupted operation represent something genuinely rare: sustained proof of capability. The company has not simply survived fifty years of industry change; it has grown its expertise, expanded its product range, and maintained the engineering standards that its reputation was built upon.

The combination of Venetian craftsmanship values with systematic investment in technological development positions Quiko uniquely. Customers seeking a gate automation system are not merely purchasing a motor and a control board. They are entering a relationship with a company whose technical knowledge, quality processes, and commitment to customer outcomes have been tested repeatedly across an extraordinary span of industry history.

For those who value dependability and peace of mind above all else in their automation solutions, this heritage is not a historical footnote , it is a present-day competitive advantage.

Conclusion

Over the course of this article, we have explored what makes a gate automation system truly dependable, traced the fifty-year journey of a company that has built its reputation on precision and steadfastness, and examined how the right combination of engineering quality, product customization, and industry experience translates into real-world value for homeowners, installers, and commercial clients alike.

The central message is simple: in automation, longevity is the ultimate proof of quality. Quiko’s five decades of continuous production in North East Italy are not just a milestone , they are a guarantee backed by thousands of successful installations and generations of customer trust.

Now we would love to hear from you. Have you ever dealt with an unreliable gate automation system? What qualities matter most to you when choosing an automation solution? Share your thoughts in the comments below , your experience could help others make a better-informed decision.

And if you found this article useful, explore our related content on home automation trends, gear motor technology, and installation best practices. Because when it comes to automation, the right knowledge is the first step toward the right choice.

Contact Quiko today and transform your entrance with 50 years of engineering excellence.

Contact us now