Types of automatic gates: a complete guide to gate automation systems

Are you considering upgrading your property’s entrance but feeling overwhelmed by the countless options available? Choosing the right automation gates system is a decision that will impact your daily convenience, security, and property value for years to come. From sliding gate motors to swing gate openers, from hydraulic systems to underground solutions, the market offers an impressive variety of technologies designed to meet different needs and preferences.

Understanding these distinctions is essential before making such an important investment. In this comprehensive guide, you will discover the key differences between automatic gate types, learn how each mechanism works, and gain the knowledge necessary to select the best gate opener system for your specific requirements. By the end, you will have all the information needed to make a confident, informed decision.

Understanding gate automation systems

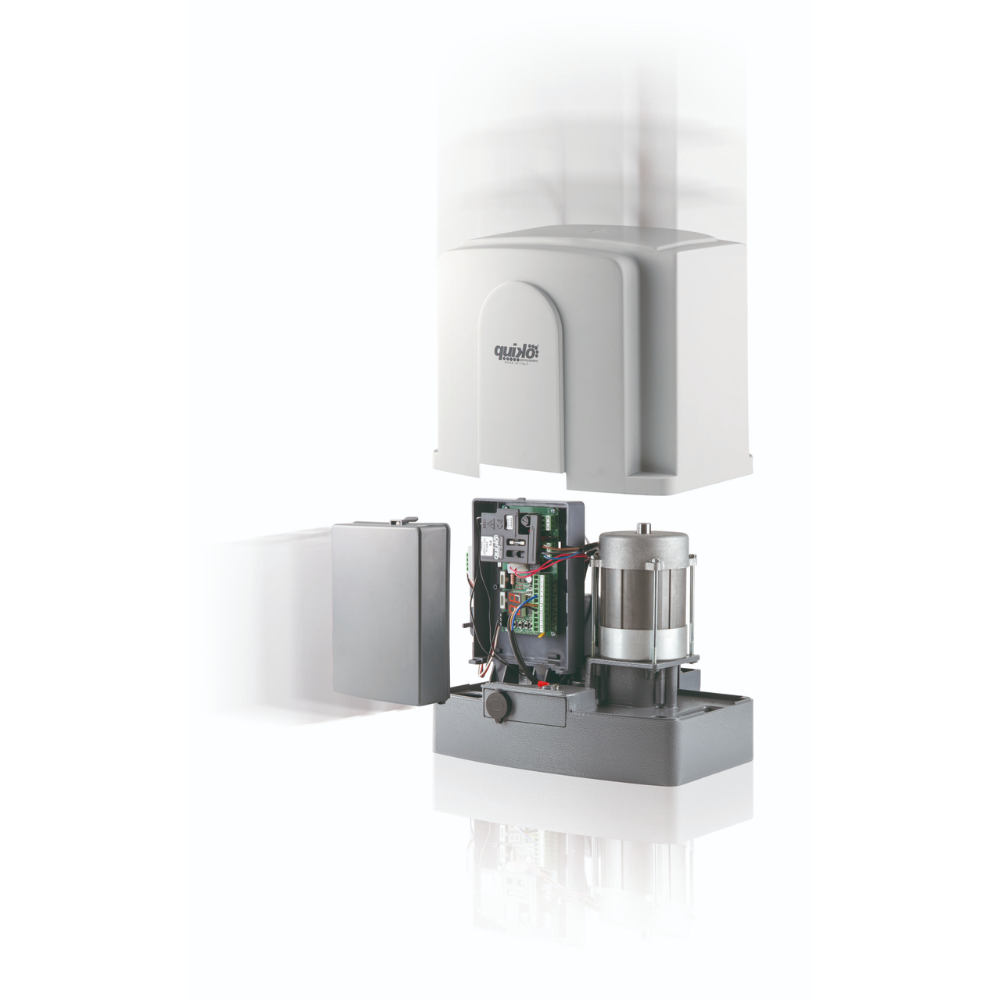

A gate automation system consists of several interconnected components working in harmony to provide smooth, reliable operation. At the heart of every system lies the gate motor, which provides the mechanical force necessary to move the gate. This motor connects to a gate opener mechanism that translates rotational energy into the specific movement pattern required by your gate type.

The gate operating system also includes control electronics, safety sensors, and remote access capabilities. Quality manufacturers engineer these components to work together seamlessly, ensuring consistent performance across thousands of operation cycles. The durability of these systems depends largely on the quality of the gear motors employed, which is why selecting a manufacturer with proven expertise in gear motor production is paramount.

Automatic sliding gates

Automatic sliding gates represent one of the most popular choices for properties with limited space or those requiring wider openings. These gates operate by moving horizontally along a track, making them ideal for driveways where swing clearance would be problematic.

Sliding gate motors and mechanisms

The sliding gate motor is specifically designed to handle the horizontal movement and weight of these gates. A sliding gate motor kit typically includes the motor unit, drive gear, mounting hardware, and control electronics. The electric motor for sliding gates engages with a rack mounted along the gate’s length, pulling or pushing the gate along its track with precision.

Modern electric sliding gate motors come in various power ratings to accommodate different gate weights and sizes. For residential applications, standard sliding gate opener motors handle gates up to 400-600 kilograms, while industrial facilities may require heavy-duty variants capable of moving gates exceeding 2,000 kilograms.

Chainless sliding gate technology

Innovation in this sector has produced the chainless sliding gate opener, which eliminates the traditional chain drive in favor of direct gear engagement. This advancement reduces maintenance requirements and operates more quietly, making it particularly suitable for residential environments where noise considerations matter.

Sliding gate kits for different applications

Complete electric sliding gate kits provide everything necessary for installation, from the motor to the gate opener remote controls. When selecting a sliding gate opener kit, consider the gate’s weight, frequency of use, and environmental conditions. Properties in coastal areas or extreme climates benefit from motors engineered with enhanced weather resistance, a feature that distinguishes premium manufacturers from standard offerings.

Request a free consultation: our experts will help you choose the perfect system for your property.

Automatic swing gates

Swing gate automation offers an elegant solution for properties where aesthetics play a crucial role. These gates pivot on hinges, opening inward or outward in an arc motion. The automatic swing gate opener category encompasses several distinct technologies, each with specific advantages.

Swing gate motors and actuators

Swing gate motors must overcome the physics of moving a gate through an arc while managing wind load and momentum. Swing gate actuators convert motor rotation into the linear or pivoting force needed to move the gate panels. The quality of these actuators directly impacts system longevity and smooth operation.

A comprehensive swing gate kit includes motors for each gate leaf (in dual configurations), mounting brackets, control units, and safety accessories. Swing gate opener kits designed by experienced manufacturers account for the specific stresses these systems encounter, engineering components to withstand thousands of cycles without degradation.

Linear actuator systems

The linear gate opener represents a refined approach to swing gate automation. Linear gate actuators extend and retract in a straight line, pushing or pulling the gate through its arc. This design offers excellent force distribution and precise control over gate movement.

Linear gate openers suit gates of moderate weight and are valued for their clean installation profile. The gate linear actuator mounts between a fixed point and the gate, operating almost invisibly while delivering reliable performance. Many property owners prefer linear swing gate operators for their aesthetic discretion and mechanical simplicity.

Articulated arm gate openers

Articulated arm gate openers employ a jointed arm mechanism that mimics the motion of a human arm opening a door. The articulated arm swing gate opener excels in applications where gate geometry or pillar positioning makes linear actuators impractical. These systems accommodate gates that open up to 120 degrees or more, providing maximum flexibility in installation scenarios.

The arm swing motor drives the articulated mechanism through a gear reduction system, delivering smooth acceleration and deceleration. This gentle operation reduces stress on gate hinges and extends the overall system lifespan.

Types of gate openers by technology

HYDRO hydraulic swing gate opener

Hydraulic gate systems

Hydraulic gate openers utilize fluid pressure to generate the force necessary for gate movement. Hydraulic gate operators are renowned for their exceptional power and smooth operation, making them the preferred choice for heavy-duty swing gate opener applications.

The hydraulic swing gate opener offers several distinct advantages. These systems provide variable speed control, soft start and stop functionality, and outstanding resistance to manual forcing attempts. Hydraulic gate operators maintain consistent performance across extreme temperature ranges, as the hydraulic fluid compensates for environmental variations.

For demanding applications such as industrial facilities or large estate entrances, hydraulic swing gate openers deliver unmatched reliability. The technology has been refined over decades, with leading manufacturers achieving exceptional durability through precision engineering and quality components.

Underground gate openers

For installations where visual impact must be minimized, the underground gate opener provides an elegant solution. Underground gate openers conceal the motor mechanism beneath the ground surface, leaving only the gate visible. This approach preserves the architectural integrity of heritage properties and high-end residential estates.

The best underground gate opener systems feature robust waterproofing and corrosion resistance, essential for equipment operating below ground level. Premium manufacturers engineer these units with drainage provisions and sealed housings that protect internal components from moisture intrusion.

Electric gate kits for various applications

Standard electric gate kits combine motor units with comprehensive control systems. An electric gates kit for residential use differs significantly from industrial configurations in terms of duty cycle ratings and safety feature requirements. Understanding these distinctions helps ensure you select appropriate equipment for your application.

Choosing the best gate opener system

Selecting the best gate opener system requires careful consideration of multiple factors. Gate weight, dimensions, and material significantly influence motor selection. Usage frequency determines the appropriate duty cycle rating, while environmental conditions dictate weatherproofing requirements.

Key selection criteria

Gate weight and size determine the power requirements for your automatic gate opener kit. Manufacturers specify maximum gate weights for each motor model, and exceeding these limits compromises both performance and longevity.

Frequency of operation matters considerably. Residential electric gate openers for driveways might cycle ten times daily, while commercial installations may require hundreds of daily operations. Motors designed for intensive use incorporate enhanced cooling and more robust internal components.

Environmental factors including temperature extremes, humidity, and exposure to salt air influence equipment selection. Manufacturers with extensive experience understand these challenges and engineer their products accordingly.

The importance of quality and reliability

When investing in gate automation, the manufacturer behind your equipment matters profoundly. Companies with decades of experience in gear motor design and production bring invaluable expertise to their products. This accumulated knowledge manifests in thoughtful engineering details that distinguish truly reliable systems from those that merely appear adequate.

Consider manufacturers who combine traditional engineering excellence with contemporary innovation. Organizations rooted in regions with strong manufacturing heritage, such as the renowned industrial tradition of Northeastern Italy, often demonstrate exceptional commitment to quality. These companies understand that automation for gates must perform flawlessly through years of service, regardless of weather conditions or usage intensity.

A manufacturer with over fifty years of experience in gear motor production has encountered and resolved countless engineering challenges. This depth of experience translates into products engineered for real-world reliability rather than merely laboratory specifications. When evaluating automation for swing gates or sliding gate systems, prioritize manufacturers who offer customizable solutions tailored to your specific requirements rather than one-size-fits-all products.

The Italian gate automation industry has earned global recognition for combining precision engineering with elegant design. This heritage of excellence, particularly from the Venetian manufacturing tradition, represents an ideal balance of innovation and proven reliability.

Explore the complete range of Quiko gear motors and find the ideal solution for your gate.

Conclusion

Throughout this guide, we have explored the essential types of automation gates available on the market, from space-saving sliding systems to elegant swing gate solutions, and from powerful hydraulic operators to discreet underground mechanisms. Each technology offers distinct advantages, and understanding these differences is the first step toward making a choice that truly fits your property and lifestyle.

The key takeaway is clear: investing in quality gate automation from experienced manufacturers ensures reliability, durability, and peace of mind for years to come. Your entrance is more than just an access point; it is a statement about your property and a daily convenience you will appreciate every single time you arrive home.

Now it is your turn to take action. Which type of automatic gate system best suits your needs? We would love to hear your thoughts and questions in the comments below. If you found this guide helpful, consider sharing it with others who might benefit from this information.

Ready to transform your property’s entrance? Explore our complete range of Italian-engineered gate automation solutions and discover why fifty years of expertise makes all the difference.