Can you reverse the way a sliding door opens?

Have you ever completed a renovation or construction project only to realize that the initially chosen sliding door opening direction obstructs your room’s flow or clashes with your furniture placement? This is a common, yet critical, issue: once installed, is it truly possible to reverse the way a sliding door opens?

For decades, the orientation (or “handing”) of these installations has been considered a fixed point,an almost immutable design constraint. In our industry, authority and expertise are everything, and our established heritage dictates that innovation must solve real-world customer problems.

In this article, we will demystify the concept of sliding door handing, explain the complexities inherent in traditional solutions, and, in line with our commitment to excellence, present you with the market-leading solution that revolutionizes flexibility. You will gain the definitive knowledge needed to navigate this decision, securing an investment that is as adaptable as it is reliable.

Understanding sliding door handing

The convenience of sliding patio doors is undeniable, offering smooth operation and maximizing usable space. However, a critical,and often misunderstood,aspect of these installations is door handing, which dictates the sliding door opening direction.

Door handing refers to the side the active panel slides toward when viewed from the exterior. This is typically described as right-hand sliding door or left-hand sliding door.

- Right-hand sliding door: The active panel (the one that moves) slides to the right, covering the fixed panel on the right.

- Left-hand sliding door: The active panel slides to the left, covering the fixed panel on the left.

Understanding how do you determine which way a sliding door opens is crucial for installation and functionality, often referencing a sliding door handing chart. This determination is typically set during the manufacturing process, making the question of reversal highly relevant for homeowners and builders.

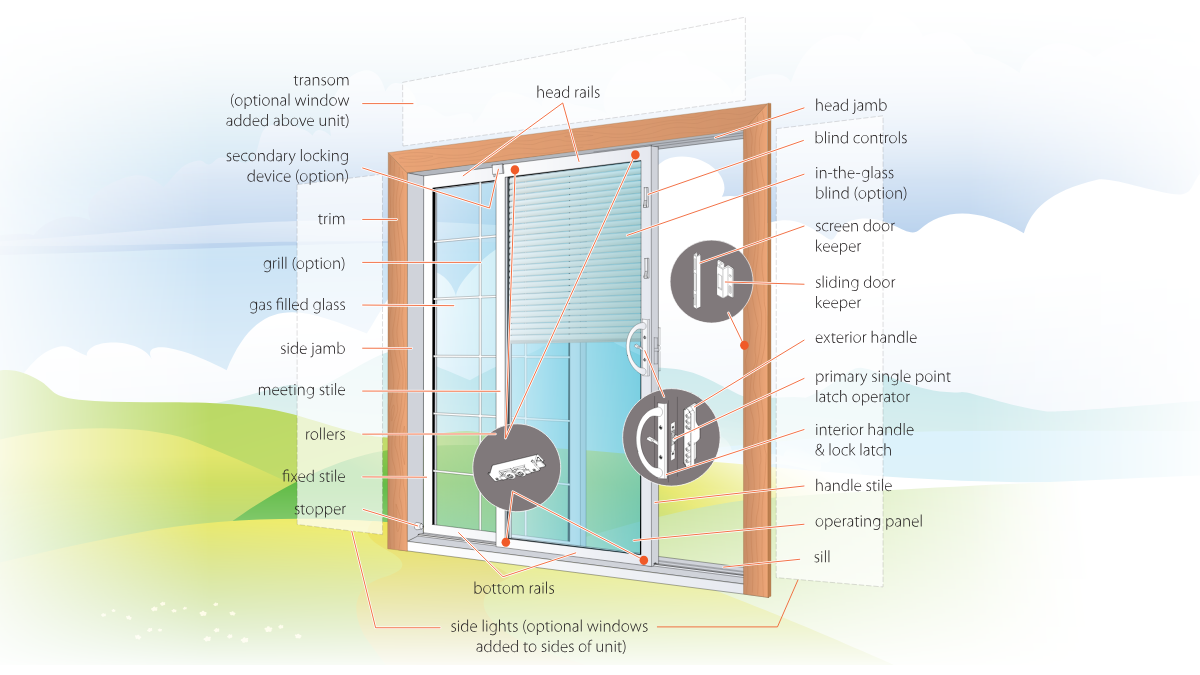

Diagram illustrating the sliding door handing chart showing the difference between Left Hand and Right Hand sliding door opening directions.

Source: https://www.bayviewwindows.ca

Can the opening direction be reversed?

A frequent query from clients concerns the possibility of altering the established sliding door opening direction: Can you change a sliding door from left to right?

For traditional sliding door systems, the answer is often complex, leaning towards no, or at least not without significant and costly modifications. The design,including the frame structure, track placement, and panel configuration,is typically manufactured to a specific handing.

Attempting to reverse the direction usually involves:

- Completely dismantling the frame and panels.

- Re-drilling and re-machining crucial components.

- Potentially compromising the door’s seals, warranty, and long-term security.

Therefore, for standard systems, the initial choice of which side does a sliding door open on is largely permanent.

Why reversing direction is challenging for traditional doors

The structural integrity and weather resistance of a sliding door rely on precision engineering. What is the rule for door opening direction is governed by fixed hardware elements:

- Fixed vs. active panel. The frame is designed to secure one panel permanently (fixed) and allow the other (active) to move. Reversing this means moving the fixed components.

- Hardware and locking mechanisms. Locks, rollers, and handles are specifically configured for one direction of travel. Swapping them often requires a full replacement of the panel itself.

- Drainage. The bottom track often includes sophisticated drainage to channel water away from the interior. Reversing the panels can disrupt this critical water-management system.

These complexities underscore why traditional systems offer limited flexibility once installed.

Stop design limits.

Discover our adaptable solutions now!

Introducing the market-leading solution: flexibility by design

At the core of our heritage lies a commitment to innovation and customer-centricity. Recognizing the need for adaptability, our premium sliding door systems have been engineered to address the very question of directional reversal, positioning them as the best solution on the market for flexibility.

Our distinct advantage is a modular design approach that makes certain models inherently adaptable:

We offer select systems designed with near-symmetrical frames and interchangeable components. This revolutionary design allows qualified technicians, in certain scenarios, to modify the sliding door opening direction post-installation with minimal disruption, effectively changing the door from left to right (or vice-versa).

This adaptability stems from our expertise and is backed by years of experience in fenestration technology. Unlike conventional doors, our system minimizes permanent structural differences between the fixed and active sides in certain core models.

Download the pro handing chart: optimize your project!

Key benefits of our adaptable sliding door systems

Choosing a solution that offers directional flexibility translates directly into tangible benefits for the homeowner or developer:

- Future-proofing design. Accommodate future renovations, changes in room layout, or furniture placement without the high cost of full door replacement.

- Reduced installation risk. Eliminate the pressure of making a permanent handing decision early in the construction phase. Our system offers a corrective measure if the initial layout proves suboptimal.

- Superior engineering. The modularity that enables directional change is a testament to the door’s overall high-quality construction and precision, maintaining performance whether installed as a right-hand sliding patio door with blinds or a simple left-hand unit.

- Simplified inventory (for trade). Dealers benefit from reduced inventory complexities, as fewer distinct door configurations need to be stocked.

This level of reliability and ease-of-use reinforces our position as an industry leader, consistently focusing on user experience alongside performance.

The importance of choosing the right direction

In this authoritative exploration, we have affirmed that while the initial determination of sliding door opening direction is critical, the rigid permanence associated with traditional doors is now an outdated constraint. We have discussed the distinction between left-hand sliding door and right-hand sliding door configurations and highlighted why conventional frames are challenging to reverse.

The key takeaway, however, rests in embracing innovation. By investing in our advanced, modular systems,the best solution on the market,you are choosing not just a door, but a future-proof architectural element. This adaptability ensures that your space remains optimized, regardless of future design changes, upholding the highest standards of reliability and customer-centricity that define our heritage.

We invite you to reflect on your current or future projects. Does your existing architecture truly support your lifestyle, or could a simple change in door handing unlock new potential? Share your thoughts and experiences with directional changes in the comments below!

Unlock flexible design.

Explore all our innovative systems today.