Why “Made in Italy” matters when choosing your gate motor

Are you considering an automated gate system but confused about why some gate motors cost significantly more than others? The answer often comes down to three simple words: Made in Italy.

When it comes to gate automation, where your motor is made matters more than most property owners realize. Italian gate motors aren’t just products,they represent decades of manufacturing expertise, strict quality standards, and engineering excellence that directly impact your daily security and convenience.

This article reveals what sets Italian-made gate motors apart, why the Made in Italy label guarantees superior reliability, and how choosing authentic Italian automation technology protects your investment for decades to come.

Discover Quiko’s complete range of Italian-engineered gate automation solutions

The italian manufacturing legacy in gate automation

Italy’s reputation for exceptional manufacturing extends far beyond fashion and automobiles. The country’s industrial districts in the North East region have cultivated specialized expertise in precision engineering and automation systems over generations. This geographical concentration of knowledge creates what experts call “cluster effects”,where skilled craftspeople, innovative engineers, and quality-focused manufacturers continuously raise industry standards together.

Italian gate motor manufacturers benefit from this heritage every single day. Unlike mass-production facilities that prioritize volume over precision, Italian workshops maintain rigorous quality control at every production stage. Each component undergoes multiple inspections, and assembly technicians possess years of specialized training that automation simply cannot replicate.

The Venetian business tradition, which has shaped commercial practices since the Renaissance, emphasizes long-term reputation over short-term profits. This philosophy directly influences how Italian manufacturers approach product development. Rather than designing gate motors with planned obsolescence (intentionally making them fail after a few years), Italian engineers create automation systems built to function reliably for 25–30 years or longer.

Think about the practical implications for your property. When you install an Italian gate motor, you’re not simply purchasing a motor, you’re investing in decades of accumulated engineering knowledge, quality materials that withstand extreme weather conditions, and manufacturing processes refined through continuous improvement. This expertise translates directly to fewer service calls, lower maintenance costs, and consistent performance year after year.

Engineering excellence: what sets italian gate motors apart

The technical superiority of Italian gate motors shows up in several critical areas that directly affect your daily experience and long-term costs..

Precision manufacturing standards

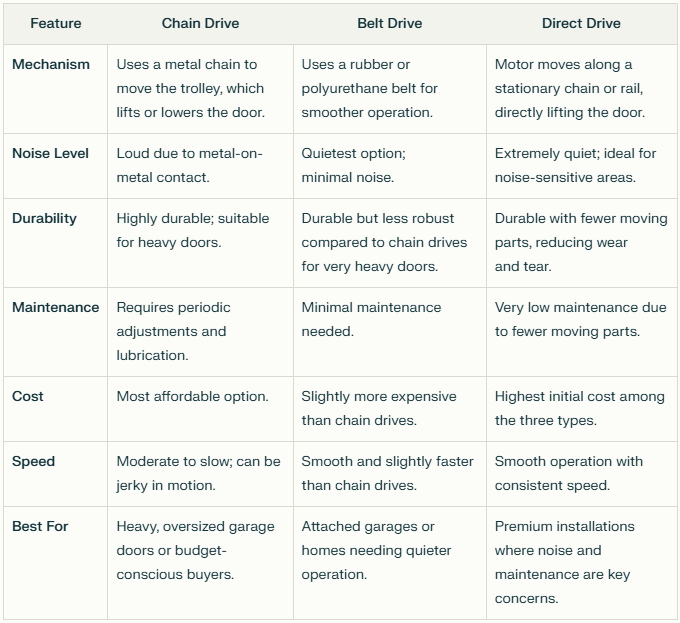

Italian manufacturers employ much tighter quality standards than industry minimums. Motors produced in Italy maintain mechanical precision that ensures smooth, quiet operation and minimal wear over time. This manufacturing precision prevents the grinding sounds, jerky movements, and premature failures common in lower-quality alternatives.

The materials selection process reflects equal rigor. Italian gate motor manufacturers use marine-grade stainless steel components (the same quality used in boats and coastal structures), weather-resistant aluminum alloys, and high-performance polymers specifically engineered for outdoor automation applications. These materials resist corrosion in coastal environments, maintain structural integrity through temperature extremes from −20°C to +55°C, and protect internal electronics from moisture infiltration.

Advanced control electronics

Modern gate automation systems require sophisticated electronic controls to manage safety sensors, obstacle detection, and smartphone integration. Italian manufacturers invest heavily in developing their own control boards, creating electronics that interpret sensor data more accurately and respond to obstacles more rapidly than generic alternatives.

This electronic sophistication becomes crucial during emergency situations. If a child runs toward your closing gate, milliseconds matter. Italian-engineered control systems process sensor inputs and reverse gate direction in under 0.3 seconds,substantially faster than the 0.8–1.2 seconds typical of budget alternatives. This response speed difference can literally prevent serious injuries to your family.

Customization capabilities

The Italian manufacturing model emphasizes flexibility and customer-specific adaptation. Unlike mass-production facilities constrained by standardized offerings, Italian manufacturers maintain the engineering expertise and production flexibility to customize motor specifications for unique applications.

Whether you need specialized mounting configurations for historic properties, motors that can operate more frequently for commercial applications, or integration with existing security systems, Italian manufacturers can adapt their products without compromising core reliability. This customization capability stems from decades of experience solving diverse automation challenges across different climates, architectural styles, and user requirements.

The venetian manufacturing tradition

Understanding the Venetian business philosophy illuminates why Italian gate motors deliver exceptional long-term value. For centuries, Venetian merchants built commercial empires by prioritizing reputation, transparency, and customer relationships over quick profits. This approach meant standing behind their products for generations.

This historical approach manifests in modern Italian manufacturing through several practical commitments. Italian gate motor producers maintain extensive technical documentation, provide detailed installation guidance, and offer genuine spare parts availability spanning decades. When you purchase an Italian gate motor today, you’re not gambling on whether parts will be available in 2040,you’re backed by companies that view your satisfaction as integral to their century-long reputation.

The customer-centric approach extends to product development. Rather than engineering gate motors in isolation, Italian manufacturers maintain ongoing dialogues with installers, end users, and industry professionals. This feedback loop ensures that new product generations address real-world challenges rather than pursuing technological novelty for its own sake.

Companies like Quiko, with over 50 years of manufacturing experience since their 1968 founding, exemplify this philosophy. Five decades of continuous operation demonstrates not just longevity, but sustained relevance,the ability to evolve technologically while maintaining core values of reliability, quality, and customer focus.

Experience Italian manufacturing excellence with Quiko’s reliable automation solutions

Quality standards and certifications

The Made in Italy designation carries legal weight backed by stringent certification requirements. Italian gate manufacturers must comply with European Union machinery directives (2006/42/EC), electromagnetic compatibility standards (2014/30/EU), and low voltage directives (2014/35/EU). These regulations mandate extensive testing protocols, safety feature verification, and documentation standards that exceed requirements in many other manufacturing regions.

Beyond mandatory compliance, leading Italian manufacturers pursue voluntary certifications demonstrating commitment to quality management systems (ISO 9001), environmental responsibility (ISO 14001), and product safety testing through independent laboratories. These certifications require regular audits, continuous improvement documentation, and transparent supply chain management.

Consider also the liability implications. In the event of a gate-related accident, documented compliance with recognized safety standards provides legal protection for property owners. Italian manufacturers’ meticulous certification and documentation practices offer peace of mind extending beyond product performance to risk management.

These motors have been independently tested and certified safe. If something goes wrong, you have documentation proving you installed a properly certified, safe product, which matters for both your conscience and your insurance.

Innovation meets heritage

The most compelling aspect of Italian gate motor manufacturing lies in the synthesis of traditional craftsmanship and cutting-edge technology. While some manufacturers choose between heritage methods and modern innovation, Italian producers successfully integrate both approaches.

Traditional metalworking expertise informs how Italian engineers design mechanical components for longevity and serviceability. Simultaneously, these manufacturers embrace advanced technologies including smartphone control integration, solar-powered backup systems for off-grid applications, and intelligent obstacle detection that distinguishes between genuine hazards and harmless environmental factors like windblown leaves.

Recent innovations from Italian manufacturers include:

- Brushless motor technology that eliminates the need for replacing worn-out carbon brushes (a common maintenance headache with older motors)

- Solar-powered backup systems perfect for properties without reliable electricity

- Smart obstacle detection that can tell the difference between a real danger (like a person or car) and something harmless (like a plastic bag blown by wind)

The innovation process itself reflects Italian manufacturing values. Rather than rushing products to market at the first sign of technological novelty, Italian manufacturers conduct extensive field testing, gather installer feedback, and refine designs through multiple iterations before commercial release. This measured approach to innovation prioritizes reliability over being first to market.

Cost vs. value: the true economics of italian gate motors

The initial price difference between Italian gate motors and budget alternatives often causes hesitation. However, a comprehensive cost analysis reveals that Italian automation systems typically deliver superior economic value over their operational lifespan.

Let’s calculate total ownership costs across 25 years,a realistic service life for quality Italian gate motors. Factor in purchase price, installation costs, maintenance expenses, energy consumption, and eventual replacement.

Budget gate motors frequently require major repairs or complete replacement within 5–7 years. Component failures necessitate emergency service calls at premium rates. Parts availability becomes uncertain as manufacturers discontinue product lines. These hidden costs quickly eclipse initial savings.

Italian manufacturers provide genuine spare parts availability spanning decades, detailed troubleshooting documentation, and service networks trained on specific product families. When maintenance becomes necessary, repair costs remain predictable and reasonable.

Beyond direct costs, consider the value of reliability itself. How much is it worth to avoid being locked outside your property due to gate motor failure? What’s the cost of security compromise when your automated gate fails to close properly? Italian gate motors minimize these intangible but significant risks through superior engineering and quality control.

Ready to invest in Italian quality?

Contact Quiko for expert guidance on the perfect gate automation solution

Conclusion

The Made in Italy label on gate motors represents far more than geographical origin,it signifies a manufacturing philosophy built on five decades of accumulated expertise, rigorous quality standards, and unwavering commitment to customer satisfaction. When you choose an Italian gate motor, you’re selecting proven reliability, superior craftsmanship, and engineering excellence that protects your investment for decades.

The economic analysis is compelling: despite higher initial costs, Italian gate motors deliver superior value through extended operational life (25–30 years vs. 5–7 years), minimal maintenance requirements, and consistent performance. The peace of mind knowing your gate automation system was engineered by manufacturers who view your satisfaction as integral to their century-long reputation has immeasurable worth.

As you evaluate gate automation options in 2026, look beyond immediate price comparisons to consider total ownership costs, reliability track records, and manufacturer reputation. The Italian manufacturing tradition offers proven solutions combining heritage craftsmanship with cutting-edge innovation, precisely what modern property automation demands.

Your gate represents the first line of security and daily convenience for your property. Choose the excellence that only Italian engineering can deliver.

Frequently asked questions

What makes Italian gate motors more reliable than other options?

Italian gate motors achieve superior reliability through precision manufacturing, premium material selection (marine-grade stainless steel, weather-resistant aluminum), rigorous quality control processes, and extensive testing protocols. The combination of traditional craftsmanship and modern engineering creates products built to last 25–30 years rather than the 5–7 years typical of budget alternatives.

Are Italian gate motors compatible with smart home systems?

Yes, modern Italian gate motors incorporate advanced control electronics supporting integration with major smart home platforms, smartphone apps, and security systems. Manufacturers design products with open protocols and standard interfaces ensuring compatibility with existing and emerging home automation technologies. You can control your gate from your phone, integrate it with Alexa or Google Home, and connect it to your security system.

How long do Italian-made gate motors typically last?

Quality Italian gate motors regularly provide reliable service for 25–30 years with appropriate maintenance (typically just an annual inspection and lubrication). Many installations from the 1990s continue operating effectively today. This longevity far exceeds the 5–7 year lifespan typical of budget alternatives, making Italian motors significantly more economical over their full operational life.

What certifications should I look for in an Italian gate motor?

Verify compliance with EU machinery directive 2006/42/EC, electromagnetic compatibility standard 2014/30/EU, and low voltage directive 2014/35/EU. Additional certifications like ISO 9001 (quality management) and independent safety testing laboratory approvals indicate manufacturer commitment to comprehensive quality standards. In simple terms: look for motors that have been independently tested and certified safe by recognized European testing laboratories.

Can Italian gate motors handle extreme weather conditions?

Yes. Italian manufacturers specifically engineer gate motors for diverse climate conditions, incorporating corrosion-resistant materials (won’t rust, even in coastal areas), sealed electronics protection (keeps moisture out), and temperature-rated components functioning from −20°C to +55°C (from well below freezing to extreme summer heat). Whether you live by the ocean, in the mountains, or in the desert, Italian gate motors are built to handle your local weather conditions reliably for decades.